It minimize the consumption of materials for acoustic and thermal insulation. It does not produce allergies.

Ceramic block with thermal and acoustic insulating qualities achieved because of the inclusion of cells in the pieces and the existence of macropores inside the material. Thermo-clay facilitates the energy saving, contributing to a sustainable development. This participation is evident in many aspects, which are manifested both in the initial phase of the industrial production of the ceramic blocks and in the construction works, for their savings in structure, in mortar, in insulating materials and in labour. Being a ceramic material, Thermo-clay makes possible the healthy construction without toxicity, radiation or allergies problems. Thermal and acoustic insulation capacity and fire resistance, characteristics that result in a greater economy, safety and comfort. Thermal conductivity (K) between 1.32 and 0.60 W/m2K, depending on the thickness. Compressive strength >100Kg/cm2. Acoustic insulation from 47 to 52.5 dBA, depending on the thickness.

Dimensions of the pieces: 30x19 cm and thicknesses of 14, 19, 24 and 29 cm.

Natural or forced ventilation throughout the surface eliminating moisture inside the walls, ceilings and floors.

Mini module allows obtaining a ventilation layer of only 3 cm without compromising the structure of the building. Placed in pavements, it creates a natural or forced ventilation in all the surface allowing the Radon gas dispersion. Placed in walls, allows creating a layer of ventilation and remove of moisture. Placed in ceilings, improves the comfort of the room and extends the life of the roof, reducing heat transmission, eliminating the moisture between the tiles and the waterproofing cover and avoiding the formation of condensation that shortens the useful life of the tiles. Made from recycled polypropylene, it is 100% recyclable.

Sanitary forging, ventilated sills, technical gaps, screeds, terraces, industrial warehouses, cold storages, sports tracks, rehabilitations and reforms, repairs of irregular and humid soils.

50x50 cm pieces.

Recycled plastic consumes considerably less energy in its production than the production of virgin materials: 2.1 MJ/kg consumed for recycled plastics compared to 61 MJ/kg for virgin plastics.

Module is a lost formwork for the realization of ventilated screeds that allows the elimination of dampness by capillarity and the dispersion of the Radon gas. Made from mixtures of non-toxic recycled plastic materials of high resistance and unalterable over time. Natural or forced ventilation throughout the surface eliminating dampness by capillarity and evacuating the Radon gas. Good thermal insulation. Easy assembly with savings in installation times (80%). Easy maintenance and modification of installations steps. Unique concreting of foundations and screed obtaining a structure of high strength and stability. The design of the upper part makes possible to level the concrete at the module level, reducing the consumption of concrete to 20 l/m2.

Sanitary forging, ventilated sills, technical gaps, screeds, terraces, industrial warehouses, cold storages, sports tracks, rehabilitations and reforms and repairs of irregular and humid soils.

Of widths of 50/58/71 cm and variable heights from 3 cm to 70 cm.

Recycled plastic consumes considerably less energy in its production than the production of virgin materials: 2.1 MJ/kg consumed for recycled plastics compared to 61 MJ/kg for virgin plastics.

Multi-module is made only and exclusively from recycled polypropylene. Its original and unique four-vault shape is ideal to cover large surfaces in very short times. It provides high levels of solidity during the placement and its particular recessed shape allows its placement even in tiered rows.

Sanitary forging, ventilated sills, technical gaps, screeds, terraces, industrial warehouses, cold storages, sports tracks, rehabilitations and reforms and repairs of irregular and humid soils.

Width of 71x71 cm and variable heights.

Recycled plastic consumes considerably less energy in its production than the production of virgin materials: 2.1 MJ/kg consumed for recycled plastics compared to 61 MJ/kg for virgin plastics.

The Soliglú piece is a modular piece measuring 66.6 x 33.3 cm in floor and 12 cm in height. It is made from recycled polypropylene plastic and offers the possibility of obtaining an aerated space in an easy, immediate and economical way. The resistance and ease of installation make it an economical and ideal solution for all types of construction works.

Sanitary forging, ventilated sills, technical gaps, screeds, terraces, industrial warehouses, cold storages, sports tracks, rehabilitations and reforms and repairs of irregular and humid soils.

66,6 x 33,3 x 10 cm. 66,6 x 33,3 x 12 cm.

Reduction of resource consumption, reduction of waste generation and it facilitates the reuse due to the modules can be transported to another location.

The three-dimensional modules are elements used as a basis for the structural calculation of multi-storey buildings, allowing a higher rigidity and inertia, compared to the traditional structure with pillars and beams. It also provides a greater speed in the execution and assembly of the structure of the building.

Reduction of resource consumption, reduction of waste generation, reuse due to the modules can be transported to another location and reduction of noise and dust during the construction process because as it is a prefabricated module, the work lasts a few days and little noise and dust is produced.

Compacthabit is a building system based on manufactured modules and fully equipped from industrial processes. The industrialization of the constructive process promotes a better quality control of the structural components and enclosures of the façade and the inner sides.

Energy: Good behaviour as a thermal insulator. Waste: No toxic or hazardous waste content.

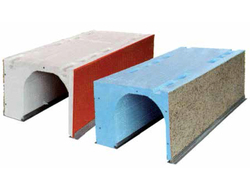

Prefabricated roller shutter box, formed by moulding extruded polystyrene and coated laterally with conglomerated fibber plates or with a hydraulic mortar plaster base. The air permeability and acoustic insulation against noise depend on the box/window connection. The walls of the box are suitable for any finish. The thermal insulation is much higher than insulation of the windows. Fire resistant rated M-1. The standard series presents the lower PVC cover and it is advisable to request the cover of another material that is not the mentioned one.

100% natural product.

Pure natural lime with double intake, first hydraulic and then aerial. Less clear than white lime, it gives the mortar specific qualities (plasticity, performance, handling, breathing,...). Its purity guarantees constancy and its resistance (100 bar) allows multiple uses without adding cement.

To carry out mason and concrete works (factories, pavements, roofs, ducts and chimneys) as well as breading and coating works.

It is presented in 35kg bags.

100% natural product.

The natural hydraulic lime is a hydraulic and powdery binder that is partially hydrated, which is obtained by calcining limestones, which contain between 15 and 20% of clay, correctly called marls. During cooking with temperatures below the clinching (approximately 1200ºC) calcium silicates, aluminates and ferroalluminates are formed, giving the binder a hydraulic nature, which is able to forge as cement and even harden under water (insoluble hydrates formation). The curing is followed by the carbonation of the "free lime", not associated with clay. This reaction is aerial (not hydraulic), it needs water or environmental humidity and carbon dioxide from the air and is responsible for the progressive resistance of the natural hydraulic lime. It varies according to its hydraulic index. Great plasticity and high workability, strong adhesion in various materials and surfaces, great water retention, little tendency to cracking, good durability, good waterproofness against water, water vapor permeability, breathability and good look. Mortars are up to a 34% more insulating than those of cement. Absence of additives and radiation index much lower than in cement.

There are a variety of products depending on their hydraulics: High Hydraulics: NHL 5. Medium hydraulics: NHL 3.5. Medium hydraulic: NHL white 3.5 Low Hydraulics: NHL 2.

100% biodegradable.

Release agent completely biodegradable in only 20 days, resulting in a totally innocuous product for the fauna and flora. Suitable for any constructing work and for any type of prefabricated.

In mild climates, with a suitable design for the passive use of solar energy, it is possible to dispense with heating and air conditioning systems.

The wood and cement conglomerate (CMC) is a lightweight concrete, made from recycled wood shavings with a homogeneous, mineralized and bonded texture with Portland cement. The wood chips are obtained from recycled old wood and the waste from the sawmills. The mineralizing treatment maintains the mechanical properties of the wood intact, stopping the processes of biological deterioration and turning the wood into a practically inert material increasing its resistance to fire. Wood chips coated with Portland cement result in a stable, compact, resistant and durable structure, while its alveolar structure allows a good thermal behaviour and provide lightness to the block. The material is resistant to water, ice and moisture and it is breathable and harmless. Properties and relevant data: Thermal insulation: The low thermal conductivity of the CMC and the additional insulation sheet of polystyrene with graphite, or cork, lead to a high thermal insulation. Thermal Inertia: The concrete mass in the interior of the wall accumulates heat during the day and transfers it slowly during the night, avoiding the thermal oscillations on the interior face of the construction, reducing the temperature peaks and the launching frequency of the installation of heating or air conditioning systems. These features increase energy savings and provide a feeling of thermal comfort. Acoustic insulation: The high mass of the wall and the acoustic absorption of the CMC, propitiate a high acoustic insulation throughout the range of auditory frequencies. The use of the system is very suitable in constructions with noise problems (nursing homes, hotels, hospitals, separation of houses, music rooms ...). High structural resistance.

The main application of the Climablock blocks is the construction of bearing walls of houses and buildings.

There are several types of blocks varying in the thermal and acoustic insulation and in the structural resistance depending on the thickness of the concrete, the insulation (polystyrene, polystyrene with graphite, cork) and the outer wall of wood and cement conglomerate. The typical dimensions are 25 cm in height, 50 cm in length and thicknesses of 15, 20, 25, 30 and 38 cm.

The use of non-renewable energies for the manufacture of a ceramic block of 1m3 involves a cost of 1600 MJ compared to 700 MJ in the case of using renewable energy. The use of biogas in the manufacturing process of the Eco Klinkers bricks reduces the 35% of the CO2 emissions.

The Eco Klinkers bricks from Piera Ecoceràmica are made from biogas, which reduces up to a 35% the CO2 emissions during the industrial process. Biogas is a clean fuel that reduces environmental pollution. The biogas used by Piera Ecocerámica comes from the treatment of organic waste buried under layers of clay from the Can Mata landfill, located in Hostalets de Pierola. Piera Ecoceramic avoids the emission into the atmosphere of 17,000 tonnes/year of CO2 as well as other greenhouse gases or ozone depleting gases. The Piera Ecoceramic biogas system allows the application of this energy source in the manufacture of the 95% of the Piera's products, contributing to a 45% of the total thermal energy used. Therefore, the manufacturing of products has a low rate of atmospheric emissions and a total commitment to respect the environment. The entire catalog of Piera Ecoceramic is compatible with the Structura system of ventilated and self-supporting façade construction that meets the requirements of the CTE.

The range of Eco Klinkers is marketed in the following models: Venice: 28 x 13.5 x 5.7 - 28 x 12 x 4.9 (cm), Bellaterra: 28 x 13.5 x 5.7 - 25 x 12 x 4.9 (cm), Red Clinker: 27.6 x 13.3 x 4.8 / 5.8 - 24 x 11.5 x 4.9 (cm), Tuareg: 28 x 13.5 x 5/6 - 24 x 11.5 x 5 (cm), Sahara: 28 x 13.5 x 5/6 - 24 x 11.5 x 5 (cm), Tundra: 28 x 13.5 x 5/6 - 24 x 11.5 x 5 (cm). The Eco Klinker from Piera Ecocerámica have a high resistance, above 55 N/mm2 and a low absorption, between the 4 and 5% on average.

Resources: Manufactured with renewable resources. Energy: Manufacturing process with low energy consumption. Energy: Good behaviour as a thermal insulator.

Cannabric is a solid block for construction based on hemp, with special thermal, acoustic and bioclimatic characteristics. It has been developed for its possible use in monolayer load-bearing walls. Due to it has a completely natural composition (plant material, natural binders and mineral binders and recycling), the block is requested by architects and developers aware of the environment and with the interest of creating more liveable, comfortable and healthy spaces, of high quality and durability. The Cannabric takes advantage of the insulating properties of hemp (with a thermal conductivity of 0.048 W/mK). Its stem is free of nutrients, so is not attacked by parasites, and therefore, any treatment is required, neither in its cultivation nor in its use in construction. The mineral components of the block provide mechanical strength, density and high thermal inertia. This results in a load-resistant construction block, with low thermal conductivity (0.1875 W/mK) and high thermal inertia (1291 kJ/m3K), which has thermophysical qualities that protect both from cold and heat, without the need to add insulators in thin-walled monolayer walls. In the binders, we work exclusively with natural materials such as soil and limes, materials that are of reduced energy consumption in their manufacture and that at the same time possess natural and bioclimatic properties. The Cannabric components have characteristics that create a pleasant climate in the home and a high acoustic comfort. They keep the air clean and regulate the humidity. Then, it is important that the mortars, possible coatings and paints are free of cement and chemical components to not alternate their properties.

The pieces of Cannabric are solid, of earthy colour and rough texture, not baked but the air is dried during a minimum time of 28 days. Whereby, they are more breathable and consume little energy in their manufacture. They are manufactured in three sizes: 30 x 14.5 x 10.5 [cm] (whole block), 14.5 x 14.5 x 10.5 (half block), 21.5 x 14.5 x 10.5 (three-fourth block). Its presentation is done on pallets of 195/252/390 units.

The ClimaBlock forging plate is a semi-resistant plate composed of a conglomerate base made of wood and cement, reinforced semibiguets and insulating material vaults (polystyrene or cork). The plate has excellent values of thermal and acoustic insulation and is an ideal support for the realization of regattas, the passage of installations and the application of plasters.

The conglomerate of wood and cement (CMC) is a lightweight concrete composed of recycled wood chips of homogeneous, mineralized and bonded texture with Portland cement. The wood chips are obtained from the recycling of old wood and waste from the sawmills. The mineralizing treatment keeps intact the mechanical properties of the wood stopping the processes of biological deterioration turning the wood into a practically inert material and increasing its resistance to fire. The wood chips covered with Portland cement result in a stable, compact, resistant and durable structure, while its alveolar structure allows a good thermal behaviour and gives lightness to the block. The material is resistant to water, ice and moisture, is breathable and harmless. Properties and relevant data: Thermal insulation: The low thermal conductivity of the CMC added to the additional polystyrene insulation slabs, or cork, allows the slab to obtain very high values of thermal insulation. Depending on the climatic zone we are in, it complies with the CTE requirements without the need for additional insulation. Acoustic insulation: The high mass of the floor and the acoustic absorption of the CMC propitiate a high acoustic isolation in the whole range of auditory frequencies. If a higher insulation is required, an absorbent sheet must be inserted under the pavement. The Climablock slab of floor allows reaching values of 53 dB of acoustic insulation to air noise and of 62 dB to impact. Rapid execution: The placement of the plate is made very agile by the use of a crane requiring little labour for the simplicity of assembly. With Climablock, the previous execution of an expensive formwork is not necessary since only the plates have to be underpinned every 2.5 m of light between the supports. The plates are customised according to the construction work and very light (45 kg/ m2) which allow a comfortable commissioning work with a high performance. About ClimaBlock, it is possible to cut, nail, screw and paste as if it was wood and it is material very easy to work with. The CMC’s base of 4.5 cm allows the passage of installations through the roof without any affection to the structure.

The main application of the ClimaBlock plate is the construction of slabs and covers for buildings.

PI plates: PI plates are characterized by having CMC vaults which gives greater resistance to the fire of the floor and have a high hardness. The lateral stiffeners of the plate form a mold that allows to form a solid structure. The plates are 100 cm wide and are manufactured with a floor thickness of 15 +5, 20 +5 and 25 +5 in lights of up to 7 meters. There is a special type of insulating plate for covers that incorporates an additional polystyrene sheet. PF plates: The PF plates have polystyrene vaults and are lighter. The plates are 120 cm wide and are manufactured by forging thicknesses of 15 +5, 20 +5 and 25 +5 cm and lights of up to 6.5 m. There are two types of vaults in this type of plate: made of polystyrene or cork.